|

|

||

|

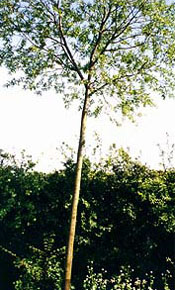

The "Salix alba caerulea" is one of six hundred or more varieties of willow. The young tree shown here, growing in Essex, England, will at approximately twelve to fifteen years be ready for felling, to be used for the manufacture of cricket bats. This white willow is chosen because it combines to the highest degree a quickness of growth, a straightness of grain and a toughness of fibre. Essex is the centre of cricket bat willow growing, as it's climate and soil suit the tree better than any other place in the world. This wood is also used for Rounders' sticks, stoolball bats, polo and skittle balls, charcoal, matches and paper pulp. |

||

|

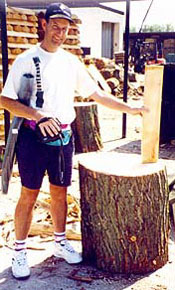

At J.S.Wright and Sons Ltd., a cross-section from a matured willow tree is ready for processing. The trunks are sawn into lengths approximating the blade of a bat. Usually about three such lengths can be obtained per tree. Cleaving the cleft from this "cut" is done with the grain using a beech wedge (also known as "riving"), the lengths being split from the centre. Bark is removed from the clefts and rough sawn into the shape of a cricket bat blade, later being graded according to it's position in the trunk, colour and straightness of grain. The cleft ends are waxed to protect the end grain from moisture and then naturally and/or kiln dried in preparation for storage prior to sale. |

|

| Willow is a very resilient wood when compressed, but in its natural form would damage easily with the ball striking the blade. The craftsmanship in the pressing process is in the judging of the timber of each blade. A blade pressed too much is dense, firm and long lasting, but has no drive. On the other hand a too lightly pressed blade has extra resilience but would not last very long. |

|

Grade one (12 piece manau cane, 3 spring rubber) handle blocks are imported from Indonesia. I turn these glued blocks to the desired diameter and cut the wedge shape for a near perfect fit to the blade assisted by a special glue. |

|

|